DIY powder coating is a great way to give old items a fresh new look. It’s a durable and long-lasting finish that can be applied to various surfaces like metal furniture, automotive parts, and even tools. Compared to traditional painting methods, powder coating offers a number of advantages, including a smoother, more even finish, better resistance to scratches and chips, and a wider range of color options.

This guide will walk you through the process of setting up your own powder coating station, choosing the right materials, and applying the coating to your projects. We’ll also cover safety precautions and troubleshooting tips to ensure a successful experience.

Setting Up Your DIY Powder Coating Station

Powder coating is a durable and attractive finish that can be applied to a wide variety of surfaces. With the right equipment and setup, you can achieve professional-quality results at home. This guide will walk you through the essential steps for creating a safe and effective powder coating station.

Choosing a Workspace

The first step is to choose a suitable workspace for your powder coating station. You’ll need a well-ventilated area that is large enough to accommodate your equipment and allow for safe movement. A garage or workshop is ideal, but a covered patio or even a well-ventilated room in your home can work as well.

Essential Equipment

Once you have a workspace, you’ll need to gather the necessary equipment. Here’s a list of essential items:

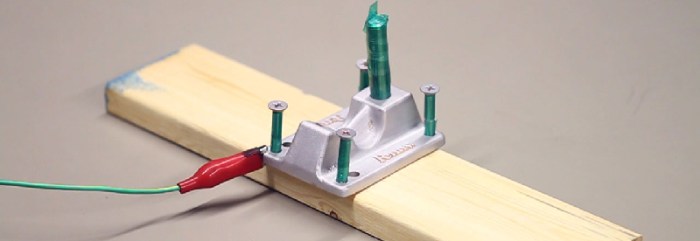

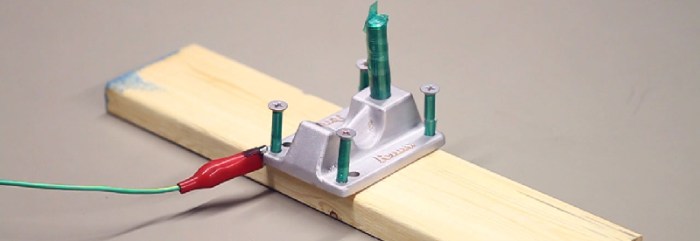

- Powder coating gun: This is the tool that will apply the powder to the surface you’re coating. Choose a gun that is compatible with the type of powder you plan to use.

- Oven: You’ll need an oven to cure the powder coating. A standard home oven can be used, but a dedicated powder coating oven will provide more consistent results.

- Compressor: A compressor is required to power the powder coating gun. Choose a compressor that can provide the necessary air pressure and volume.

- Safety gear: Powder coating involves working with chemicals and dust, so it’s essential to wear appropriate safety gear. This includes a respirator, gloves, and eye protection.

- Cleaning supplies: You’ll need cleaning supplies to prepare surfaces for powder coating and to clean up any spills or overspray.

- Grounding system: A grounding system is essential for safety and helps prevent static electricity build-up.

Table Layout

A well-organized table layout will make your powder coating process more efficient and safe. Consider the following arrangement:

| Equipment | Placement |

|---|---|

| Powder coating gun | Center of the table, within easy reach |

| Compressor | Near the powder coating gun, with hoses connected |

| Cleaning supplies | On one side of the table, organized and easily accessible |

| Safety gear | Within easy reach, near the cleaning supplies |

Ventilation, Diy powder coat

Proper ventilation is crucial for a safe and effective powder coating station. The powder coating process generates dust and fumes that can be harmful if inhaled. Here are some tips for creating a well-ventilated workspace:

- Open windows and doors: This will allow fresh air to circulate and help remove dust and fumes.

- Use exhaust fans: Install exhaust fans to draw out air from the workspace and vent it outside.

- Wear a respirator: Even with good ventilation, it’s essential to wear a respirator to protect yourself from dust and fumes.

Applying the Powder Coating

Applying powder coating using a powder coating gun requires precision and a steady hand. This section will guide you through the process, offering tips on achieving even coverage and avoiding over-application.

Applying Powder Coating with a Gun

Using a powder coating gun is the most common method for applying powder coating. The gun works by using compressed air to atomize the powder and propel it towards the workpiece. The powder then adheres to the workpiece, forming a coating.

- Hold the gun at a consistent distance: The distance between the gun and the workpiece is crucial for achieving even coverage. Typically, a distance of 6-8 inches is recommended. Holding the gun too close can result in a thick, uneven coating, while holding it too far away can lead to a thin, patchy coating.

- Maintain a consistent speed: Move the gun smoothly and consistently over the workpiece, avoiding sudden stops or changes in direction. This will help to ensure that the powder is applied evenly.

- Overlap the passes: Overlap each pass by about 50% to ensure complete coverage. This will also help to prevent the formation of thin spots.

- Avoid over-application: Too much powder can lead to a thick, uneven coating that is prone to defects. It is better to apply multiple thin coats than one thick coat.

Handling and Storing Powder Coating Materials

Proper handling and storage of powder coating materials are essential for maintaining their quality and ensuring safe operation.

- Keep powder coating in a dry, cool place: Powder coating is hygroscopic, meaning it absorbs moisture from the air. Excessive moisture can cause the powder to clump and become unusable. Store the powder in airtight containers in a dry, cool environment.

- Avoid exposure to direct sunlight: Direct sunlight can degrade the powder coating, affecting its quality and performance. Store the powder in a shaded area or in a container that blocks UV rays.

- Handle the powder coating carefully: Powder coating is a fine powder that can be easily dispersed into the air. Avoid creating dust clouds when handling the powder. Use a respirator to protect yourself from inhaling the powder.

Tips for Achieving Even Coverage

To ensure a smooth and even powder coating, consider these additional tips:

- Clean the workpiece thoroughly: A clean workpiece is essential for proper adhesion. Remove any dirt, grease, or rust from the surface before applying the powder coating.

- Use a preheating method: Preheating the workpiece before applying the powder coating can improve adhesion and reduce the risk of defects. A preheating temperature of 150-200°F is generally recommended.

- Avoid applying powder coating to sharp edges: Sharp edges can cause the powder coating to build up, creating a thick, uneven coating. Round off any sharp edges before applying the powder coating.

Curing the Powder Coating

Curing is the final step in the powder coating process, where the powder transforms into a durable, protective coating. This is achieved by heating the coated object in an oven, causing the powder to melt, flow, and chemically bond to the surface.

Oven Curing Process

The curing process involves placing the coated object in an oven that has been preheated to a specific temperature for a set amount of time. The heat melts the powder particles, causing them to fuse together and form a continuous coating. The chemical reactions that occur during this process create a strong bond between the coating and the substrate.

Curing Temperature and Time

The curing temperature and time are critical factors that determine the quality and durability of the powder coating. These parameters vary depending on the type of powder coating used.

- Epoxy Powder Coatings: These coatings typically cure at temperatures between 350°F (177°C) and 400°F (204°C) for 10-20 minutes.

- Polyester Powder Coatings: These coatings generally cure at temperatures between 375°F (191°C) and 425°F (218°C) for 15-25 minutes.

- Hybrid Powder Coatings: These coatings combine the properties of epoxy and polyester coatings and cure at temperatures between 350°F (177°C) and 400°F (204°C) for 15-20 minutes.

Note: Always consult the manufacturer’s specifications for the specific powder coating you are using to determine the optimal curing temperature and time.

Importance of Cooling

After the curing process, it is crucial to allow the powder coating to cool completely before handling. This is because the coating is still soft and vulnerable to damage when hot. Rapid cooling can cause stress on the coating, leading to cracking or other defects.

With a little practice and the right equipment, you can achieve professional-looking results with DIY powder coating. It’s a rewarding process that allows you to customize and personalize your projects while saving money and adding a touch of unique style. So why not give it a try?

DIY powder coating is a great way to give your projects a durable and attractive finish. If you’re looking for a project that will really stand out, consider building a loft bed using loft bed plans diy. You can then powder coat the metal frame for a sleek and modern look that will last for years to come.

The possibilities are endless with DIY powder coating!