DIY Wire Bender: Embark on a journey of crafting and creativity with a DIY wire bender. This versatile tool opens up a world of possibilities, allowing you to shape metal wire into unique and functional designs. From intricate jewelry pieces to sturdy garden structures, the applications are as boundless as your imagination.

Building your own wire bender offers a rewarding experience, empowering you to customize the tool to meet your specific needs. This guide will walk you through the process, from selecting materials to mastering bending techniques, equipping you with the knowledge to create your own custom wire bender.

Introduction to DIY Wire Benders

A DIY wire bender is a tool that allows you to create custom shapes and bends in wire, giving you the freedom to create unique and personalized projects. This is a versatile tool that can be used for a wide range of purposes, from crafting jewelry and sculptures to creating functional items like hooks and hangers.

Benefits of DIY Wire Benders

DIY wire benders offer several advantages over commercially available options, primarily due to their customizable nature and potential cost savings.

- Cost-Effectiveness: Building your own wire bender can be significantly cheaper than purchasing a pre-made tool, especially if you already have some of the necessary materials.

- Customization: DIY wire benders allow you to tailor the design and size of the bender to meet your specific project requirements. You can create a bender that perfectly fits the wire gauge and shape you need.

- Flexibility: DIY wire benders are highly adaptable and can be used to create a variety of bends and shapes, depending on the design and materials used.

Examples of Projects Using DIY Wire Benders

DIY wire benders can be used to create a wide range of projects, showcasing their versatility and creative potential. Here are a few examples:

- Jewelry: Wire benders can be used to create earrings, bracelets, necklaces, and rings. By bending wire into intricate shapes, you can create unique and personalized pieces.

- Sculptures: Wire benders are essential tools for creating wire sculptures, allowing you to form wire into complex and expressive shapes.

- Functional Items: You can create functional items like hooks, hangers, and plant stands using a wire bender. These projects can be both practical and decorative.

Materials and Tools

A DIY wire bender is a versatile tool for various tasks, from crafting jewelry to bending metal for small-scale projects. To build one, you’ll need a few basic materials and tools, which are readily available at hardware stores and online retailers.

Materials and Tools

| Name | Description | Source |

|---|---|---|

| Wood | A sturdy piece of wood, such as plywood or hardwood, serves as the base for the bender. | Hardware stores, lumberyards |

| Metal Rod | A metal rod, usually steel or aluminum, acts as the bending surface. | Hardware stores, metal suppliers |

| Screws | Screws are used to secure the metal rod to the wood base. | Hardware stores |

| Clamps | Clamps are helpful for holding the wood base securely in place while you work. | Hardware stores |

| Measuring Tape | A measuring tape is essential for accurately marking the metal rod and ensuring consistent bends. | Hardware stores |

| Marker | A marker is used to mark the metal rod before bending. | Hardware stores |

| Hammer | A hammer is used to secure the metal rod to the wood base. | Hardware stores |

| Safety Glasses | Safety glasses protect your eyes from flying debris during bending. | Hardware stores |

| Work Gloves | Work gloves provide protection for your hands while handling metal. | Hardware stores |

Types of DIY Wire Benders

This section will explore different DIY wire bender designs, examining their strengths and weaknesses. By understanding the pros and cons of each design, you can choose the best option for your specific wire bending needs.

Basic Hand-Held Bender

The basic hand-held wire bender is the simplest design, consisting of a metal bar with a fixed bend or groove. This type of bender is easy to make and use, and it’s suitable for bending small gauge wires.

- Strengths: Simple design, easy to make and use, affordable.

- Weaknesses: Limited bending capacity, not suitable for larger gauge wires or complex shapes.

Lever-Action Bender

Lever-action benders offer increased leverage, allowing you to bend thicker wires. These benders typically have a handle and a lever arm that applies pressure to the wire.

- Strengths: Greater bending capacity, suitable for thicker wires, provides more leverage.

- Weaknesses: More complex design, requires more materials, can be bulkier.

Adjustable Bending Tool

Adjustable benders are versatile tools that can bend wires to different angles and radii. These benders typically have adjustable arms or jaws that can be set to the desired bending parameters.

- Strengths: Versatility, adjustable bending angles and radii, can be used for a wider range of wire sizes.

- Weaknesses: More complex design, requires more precision, can be more expensive.

Table, Diy wire bender

Here’s a table comparing the different DIY wire bender designs:

| Design | Strengths | Weaknesses | Applications |

|---|---|---|---|

| Basic Hand-Held Bender | Simple, easy to make, affordable | Limited capacity, not suitable for thick wires or complex shapes | Bending small gauge wires, simple shapes |

| Lever-Action Bender | Greater capacity, suitable for thicker wires, provides leverage | More complex design, requires more materials, can be bulkier | Bending thicker wires, simple shapes |

| Adjustable Bending Tool | Versatility, adjustable bending angles and radii, can be used for a wider range of wire sizes | More complex design, requires more precision, can be more expensive | Bending various wire sizes, complex shapes, precise angles |

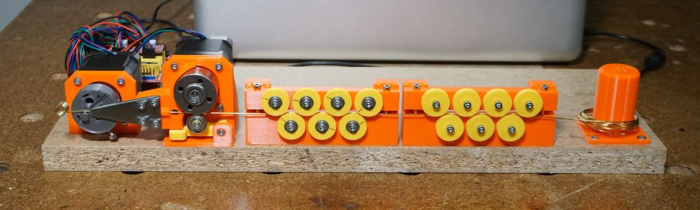

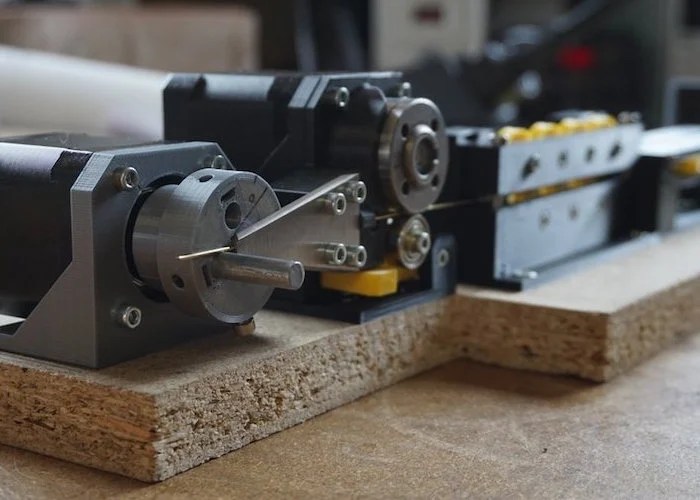

Building a DIY Wire Bender

Building a DIY wire bender is a simple and cost-effective way to create custom shapes from wire. You can use it for various projects, from crafting jewelry to building small structures. This guide will walk you through the steps of building a basic wire bender using readily available materials.

Materials and Tools

Before you begin, gather the necessary materials and tools. You will need:

- A piece of hardwood or plywood (approximately 12 inches long and 4 inches wide)

- A piece of metal rod or dowel (about 1/2 inch in diameter and 6 inches long)

- Wood screws or nails

- A drill with a drill bit slightly smaller than the diameter of your metal rod

- A hammer (if using nails)

- A saw (for cutting the wood)

- Sandpaper (for smoothing the edges)

- Optional: A vise or clamp (for holding the wood while drilling)

Constructing the Wire Bender

Now, let’s build the wire bender.

- Cut the wood: Cut the hardwood or plywood to the desired size. You can adjust the length and width based on your project needs.

- Drill the hole: Using a drill and the appropriate drill bit, drill a hole in the center of the wood piece. The hole should be slightly smaller than the diameter of the metal rod.

- Insert the metal rod: Carefully insert the metal rod into the drilled hole. Ensure it fits snugly and doesn’t wobble.

- Secure the rod: If using screws, drive them through the wood and into the metal rod to secure it in place. If using nails, hammer them in, ensuring they are flush with the wood’s surface.

- Sand the edges: Smooth any rough edges on the wood with sandpaper. This ensures a safe and comfortable grip while bending the wire.

Using the DIY Wire Bender

Once the wire bender is assembled, you can start bending wires.

- Place the wire: Position the wire over the metal rod, ensuring it rests securely against the wood.

- Apply pressure: Gently apply pressure to the wire, bending it around the metal rod. The tighter the bend, the more force you will need to apply.

- Experiment: Experiment with different wire gauges and bending angles to create a variety of shapes.

Using a DIY Wire Bender

Now that you have your DIY wire bender built, it’s time to put it to use. Using a wire bender is a simple process, but it does require some practice to get the hang of it. With a little patience and experimentation, you’ll be able to create a variety of shapes and angles with ease.

Bending Techniques

To bend wire using a DIY wire bender, you’ll need to follow a few basic steps. First, place the wire in the bender’s groove, ensuring that the wire is securely held in place. Next, use the lever or handle to apply pressure to the wire, bending it to the desired angle. You can adjust the angle by moving the wire along the bender’s groove or by changing the pressure applied to the lever.

- Simple Bends: For simple bends, place the wire in the bender’s groove and apply pressure to the lever. The angle of the bend will depend on the amount of pressure applied and the position of the wire in the groove.

- Right Angle Bends: To create right angles, use a bender with a 90-degree groove. Position the wire in the groove and apply pressure to the lever until the wire bends to a 90-degree angle.

- Curved Bends: For curved bends, use a bender with a curved groove. Position the wire in the groove and apply pressure to the lever, slowly moving the wire along the groove to create a smooth curve.

- S-Shaped Bends: To create S-shaped bends, use a bender with two grooves, one for each bend. Position the wire in the first groove and apply pressure to the lever to create the first bend. Then, move the wire to the second groove and apply pressure to the lever to create the second bend.

Visual Guide

Here’s a visual guide to help you understand the different bending techniques:

* Simple Bend: Imagine a straight wire. Place it in the bender’s groove and apply pressure to the lever, creating a single bend.

* Right Angle Bend: Think of a wire bent at a perfect 90-degree angle, forming an “L” shape. This is achieved by placing the wire in the bender’s 90-degree groove and applying pressure.

* Curved Bend: Visualize a smooth, rounded curve. To create this, use a bender with a curved groove and slowly move the wire along the groove while applying pressure.

* S-Shaped Bend: Picture an “S” shape formed by two consecutive bends. To achieve this, use a bender with two grooves, one for each bend, and apply pressure to the lever while moving the wire from one groove to the other.

Safety Precautions

While DIY wire benders can be a valuable tool for various projects, it’s essential to prioritize safety during their construction and use. Failing to take proper precautions can lead to injuries, so it’s crucial to understand the potential hazards and implement safety measures.

Potential Hazards

Understanding the potential hazards associated with DIY wire benders is essential for safe operation. These hazards can range from minor cuts to more serious injuries if proper precautions are not taken.

- Sharp Edges: DIY wire benders often involve sharp edges on metal components, which can cause cuts or punctures. It’s important to handle these tools with care and wear appropriate protective gear, such as gloves.

- Pinch Points: Moving parts in DIY wire benders, especially those with levers or cranks, can create pinch points. These areas can trap fingers or other body parts, leading to crushing injuries. Exercise caution when operating the tool and avoid placing hands or fingers near moving parts.

- Flying Debris: When bending wire, especially with thicker gauges, there’s a risk of metal shavings or fragments flying off. Wear safety glasses to protect your eyes from these projectiles.

- Overloading: Using a DIY wire bender beyond its intended capacity can lead to tool failure, potentially causing injuries. It’s crucial to select a wire bender appropriate for the wire gauge and avoid bending wires exceeding its capacity.

Safe Handling and Operation

Safe handling and operation of DIY wire benders are paramount to prevent accidents. Following these tips can minimize the risk of injuries.

- Inspect Before Use: Always inspect the DIY wire bender for any damage or wear before each use. Ensure all bolts, nuts, and other fasteners are securely tightened and that there are no loose or broken parts. If you notice any damage, repair or replace the tool before using it.

- Wear Protective Gear: Always wear appropriate protective gear, including safety glasses, gloves, and closed-toe shoes. Gloves will protect your hands from sharp edges and cuts, while safety glasses will shield your eyes from flying debris. Closed-toe shoes will protect your feet from potential dropped objects or falling tools.

- Use Proper Technique: Use the correct bending technique for the type of wire and the DIY wire bender you are using. Refer to the instructions provided with the tool or consult online resources for proper bending techniques. Avoid using excessive force, as it can damage the tool or lead to injuries.

- Keep Workspace Clean: Keep your workspace clean and free of clutter. This will help prevent tripping hazards and ensure you have a clear view of the area when working. Remove any debris or metal shavings after each use.

- Store Properly: Store the DIY wire bender in a safe and secure location, away from children and pets. This will help prevent accidental injury and ensure the tool is protected from damage.

Troubleshooting Common Problems

While DIY wire benders can be a valuable addition to your toolkit, you may encounter some challenges during use. This section will explore common issues and provide practical solutions to help you overcome them.

Common Problems and Solutions

Here are some common problems you might face while using a DIY wire bender and their solutions:

| Problem | Solution | Additional Information |

|---|---|---|

| Bends are inconsistent or uneven. | Ensure the wire is securely held in the bender and that the bending arm is moving smoothly. Check for any loose screws or bolts. | Use a vice or clamp to secure the wire for greater stability during bending. |

| Wire breaks or kinks during bending. | Use a wire bender designed for the appropriate gauge of wire. Avoid excessive force and use a gradual bending motion. | If the wire is too thick for the bender, consider using a different tool or bending the wire in smaller increments. |

| The bender is not bending the wire to the desired angle. | Adjust the bender’s angle setting and make sure the wire is positioned correctly. | Experiment with different bending angles to find the optimal setting for your needs. |

| The bender is not bending the wire smoothly. | Check for any obstructions or debris in the bending mechanism. Clean and lubricate the bender’s moving parts. | Regular maintenance and lubrication can help prevent wear and tear on the bender. |

| The bender is not durable enough for frequent use. | Consider using a sturdier material for your bender, such as metal or reinforced plastic. | Investing in a high-quality bender can ensure long-term durability and performance. |

Advanced DIY Wire Bender Projects

Taking your DIY wire bending skills to the next level can open up a world of possibilities, allowing you to create intricate and specialized designs. This section explores some advanced DIY wire bender projects, highlighting the challenges and solutions involved in their creation.

Designing for Specific Applications

Designing a wire bender for a specific application requires careful consideration of the wire material, diameter, and the desired bend shape.

- Custom Shapes: For complex shapes, you might need to combine multiple bending operations or utilize a more sophisticated bender design. For example, creating a spiral shape might require a bender with a rotating arm or a mechanism that allows for controlled twisting of the wire.

- Specialized Applications: Some projects might require specialized wire benders, such as those used in jewelry making, electronics, or even medical devices. These benders often incorporate features like adjustable bending angles, precise control over the bending radius, and specialized tools for holding and manipulating the wire.

Challenges and Solutions in Advanced Projects

Building advanced DIY wire benders presents unique challenges, but with careful planning and execution, these challenges can be overcome.

- Precision and Accuracy: Achieving high precision and accuracy in bending requires a well-designed bender with tight tolerances and robust construction. Using high-quality materials and ensuring proper alignment of components is crucial.

- Complexity of Design: Advanced projects often involve complex mechanisms and multiple moving parts. This requires a thorough understanding of mechanical principles and the ability to design and assemble the bender with precision.

- Safety Considerations: As the complexity of the bender increases, so do the potential safety risks. It’s essential to incorporate safety features, such as guards, emergency stops, and proper wiring, to protect the user.

Examples of Advanced DIY Wire Bender Projects

- CNC-Controlled Wire Bender: This project involves integrating a CNC controller with a wire bender, allowing for precise and automated bending of complex shapes. This approach is particularly useful for high-volume production or for creating intricate designs that require consistent accuracy.

- Pneumatic Wire Bender: Utilizing pneumatic actuators, this project creates a powerful and versatile wire bender capable of handling larger diameter wires and producing more forceful bends. The pneumatic system allows for precise control over the bending force and speed.

- Wire Forming Machine: This project aims to build a machine that can bend and shape wire into three-dimensional forms, such as wire sculptures or custom brackets. The machine might incorporate multiple bending stations, adjustable tooling, and a programmable control system.

Alternatives to DIY Wire Benders

While DIY wire benders offer a cost-effective and customizable solution, there are alternative methods for bending wire without the need for a dedicated tool. These alternatives can be particularly useful if you only need to bend wire occasionally or if you prefer a simpler approach.

This section explores different alternatives to DIY wire benders, comparing their advantages and disadvantages to help you determine the best method for your needs.

Manual Bending Techniques

Manual bending techniques involve using your hands and simple tools to bend wire. This method is suitable for small-scale projects and simple shapes.

Here are some common manual bending techniques:

- Hand Bending: This technique involves using your hands to bend the wire directly. It’s suitable for small, simple bends, but can be difficult for thicker wires or complex shapes.

- Using Pliers: Pliers provide leverage and control, making them ideal for bending wire into various shapes. You can use different types of pliers, such as needle-nose pliers, for precise bending or channel lock pliers for stronger bends.

- Using a Hammer and Anvil: This technique is best suited for bending thicker wires and creating more robust shapes. You can use a hammer to strike the wire against an anvil, bending it to the desired shape.

Specialized Tools

Specialized tools offer greater precision and control for bending wire, particularly for intricate shapes or larger projects.

- Wire Bending Machines: These machines are designed for industrial applications, providing high-speed and accurate bending. They are typically used for mass production of wire forms.

- Wire Bending Jigs: Jigs are templates that guide the bending process, ensuring consistent and accurate shapes. They are available for various shapes and sizes of wire.

- Tube Benders: Tube benders are designed for bending metal tubes, but they can also be used for bending wire. They offer precise bending control and are suitable for creating complex curves.

Comparison Table

Here is a table comparing DIY wire benders with alternative methods:

| Method | Advantages | Disadvantages |

|---|---|---|

| DIY Wire Bender | Customizable, cost-effective, versatile | Requires construction, may be less precise |

| Manual Bending Techniques | Simple, readily available tools, no setup required | Limited accuracy, difficult for complex shapes, can be physically demanding |

| Specialized Tools | High precision, efficient for mass production, suitable for complex shapes | Costly, may require specialized training, limited customization |

Inspiration and Ideas

DIY wire benders offer a world of creative possibilities, allowing you to transform simple wire into unique and functional pieces. From intricate jewelry designs to sturdy garden structures, the applications are truly limitless. Let’s explore some inspiring examples and delve into the creative potential of wire bending.

Examples of Wire Bending Projects

Here are some inspiring examples of projects that can be created using DIY wire benders:

| Project Name | Description | Image |

|---|---|---|

| Wire Sculpture | A wire sculpture can be a beautiful and unique piece of art, often incorporating intricate details and flowing lines. | Imagine a sculpture of a bird in flight, its wings gracefully outstretched, crafted from thin wire. The wire’s flexibility allows for the capture of delicate movement and intricate details, creating a visually captivating piece. |

| Wire Jewelry | Wire jewelry is a popular and versatile craft, allowing for the creation of earrings, necklaces, bracelets, and more. | Think of a pair of delicate earrings, each shaped like a delicate flower, crafted from silver wire. The wire’s malleability allows for the creation of intricate petals and delicate details, resulting in a beautiful and unique piece of jewelry. |

| Wire Garden Art | Wire can be used to create decorative elements for your garden, such as wind chimes, plant stakes, or even small sculptures. | Picture a set of wind chimes crafted from copper wire, each chime shaped like a leaf. The wind gently passing through the chimes creates a soothing and melodic sound, adding a touch of whimsy to your garden. |

| Wire Furniture | While more challenging, wire can be used to create unique and functional furniture pieces, such as chairs, tables, or even beds. | Envision a stylish and modern chair, its frame crafted from sturdy steel wire. The wire’s strength and flexibility allow for a unique and comfortable design, adding a touch of industrial chic to any space. |

Creative Applications of Wire Bending

Wire bending can be incorporated into a wide range of crafts and hobbies, offering endless possibilities for creative expression:

- Jewelry Making: Wire bending is a fundamental skill in jewelry making, allowing for the creation of intricate designs and delicate details. From simple wire wraps to complex woven patterns, wire bending adds a unique touch to jewelry pieces.

- Sculpting: Wire bending is a versatile medium for sculpting, allowing for the creation of both abstract and realistic pieces. The wire’s flexibility and strength allow for the creation of dynamic forms and intricate details, making it an ideal medium for expressing artistic vision.

- Garden Art: Wire bending can be used to create decorative elements for your garden, such as wind chimes, plant stakes, or even small sculptures. The wire’s durability and weather resistance make it an ideal material for outdoor projects.

- Home Decor: Wire bending can be used to create unique and functional home decor items, such as picture frames, candle holders, or even wall art. The wire’s versatility allows for the creation of both simple and elaborate designs, adding a personal touch to your home.

- Model Making: Wire bending is a valuable skill in model making, allowing for the creation of intricate structures and details. The wire’s flexibility and strength make it ideal for creating realistic models of vehicles, buildings, and other objects.

- Upcycling: Wire bending can be used to upcycle old or discarded items, giving them a new life and purpose. For example, you can use wire to create a new handle for a broken chair or to add a decorative element to an old lampshade.

Conclusion

Building a DIY wire bender offers a rewarding experience, allowing you to create custom shapes and designs for various projects. However, it’s essential to consider the limitations and challenges involved.

While DIY wire benders provide flexibility and cost-effectiveness, they may not always offer the same level of precision and durability as commercially available tools. The construction process can also be time-consuming, requiring specific skills and tools.

Exploring the Possibilities

Experimenting with different wire gauges, bending techniques, and materials can lead to exciting and unique creations. Whether you’re crafting intricate jewelry pieces, functional furniture, or decorative sculptures, a DIY wire bender empowers you to bring your ideas to life.

Resources for Inspiration

Numerous online resources and communities offer inspiration and guidance for DIY wire bending projects. Websites dedicated to crafting, metalworking, and jewelry making often feature tutorials, design ideas, and step-by-step instructions. Additionally, social media platforms like Pinterest and Instagram provide a vast collection of wire bending projects, showcasing the diverse possibilities of this versatile technique.

With a DIY wire bender, you’ll discover a new level of crafting freedom, turning simple wire into intricate works of art. Whether you’re a seasoned artisan or a curious beginner, the world of wire bending awaits. Explore the possibilities, experiment with different designs, and let your creativity take shape with the power of a DIY wire bender.

A DIY wire bender can be a handy tool for all sorts of projects, from crafting jewelry to building custom electronics. If you’re working on a project that involves bending wire, you’ll want to make sure you have the right tools for the job. And if you’re looking to save some money on your next car maintenance project, you might want to check out DIY tire balancing.

It’s a surprisingly simple process that can be done at home with a few basic tools. Once you’ve got your wire bending project under control, you’ll be ready to tackle any challenge that comes your way!