DIY Wood Lathe: Embark on a journey into the world of woodturning by crafting your own lathe. This project allows you to delve into the fundamental principles of woodturning, explore the intricacies of lathe construction, and ultimately gain a deep appreciation for the art of creating beautiful, functional pieces of wood.

From selecting the right materials and tools to mastering the techniques of woodworking and metalworking, building a DIY wood lathe is a rewarding experience. This guide will provide you with the knowledge and skills necessary to embark on this exciting adventure, transforming your workshop into a haven for woodturning creativity.

Introduction to DIY Wood Lathes

Woodturning is a captivating craft that transforms a simple block of wood into a beautiful and functional object. It involves rotating the wood on a lathe, using specialized tools to shape and refine its surface. The process is both artistic and technical, requiring a combination of skill, patience, and precision.

Types of DIY Wood Lathes

There are several types of DIY wood lathes, each with its unique features and advantages. These lathes can be categorized based on their design, power source, and intended use.

- Spindle Lathes: These are the most common type of wood lathe. They consist of a bed with two headstocks, one at each end. The wood is mounted between the headstocks, and the headstock on one end rotates the workpiece. Spindle lathes are ideal for creating symmetrical objects like bowls, vases, and table legs.

- Mini Lathes: These compact lathes are designed for smaller projects, such as pens, ornaments, and small bowls. They are often powered by a motor and have a smaller swing capacity than full-size lathes.

- Faceplate Lathes: These lathes use a faceplate, which is a flat plate attached to the headstock, to hold the workpiece. They are suitable for projects that require turning a flat surface, such as platters, clocks, and boxes.

- Variable Speed Lathes: These lathes allow you to adjust the speed of the workpiece rotation, which is essential for controlling the cutting process and achieving a smooth finish.

Benefits of Building Your Own Wood Lathe

Building your own wood lathe can be a rewarding experience. Here are some benefits of taking on this project:

- Cost Savings: Building your own lathe can be significantly cheaper than purchasing a pre-made lathe, especially if you use salvaged or reclaimed materials.

- Customization: You can design and build a lathe that meets your specific needs and preferences. This allows you to choose the size, features, and power source that best suit your woodworking style.

- Increased Understanding: Building a lathe provides a deeper understanding of its mechanics and operation. This knowledge can be valuable when troubleshooting problems or modifying your lathe in the future.

Essential Components of a DIY Wood Lathe

A DIY wood lathe is a valuable tool for woodworkers of all skill levels, offering a wide range of turning possibilities. Understanding the essential components and their functions is crucial for building a functional and safe lathe. This section will delve into the key parts of a DIY wood lathe and explain their roles in the turning process.

Headstock

The headstock is the heart of the wood lathe, housing the motor and spindle. It is responsible for rotating the workpiece.

- Motor: The motor provides the power to spin the spindle, which is typically powered by electricity. The motor’s power output determines the lathe’s speed and capacity.

- Spindle: The spindle is a rotating shaft that connects to the motor and extends through the headstock. The workpiece is secured to the spindle using a chuck or faceplate.

- Speed Control: Most DIY wood lathes feature a speed control mechanism, allowing you to adjust the spindle’s rotation speed based on the type of wood and turning project.

- Bearing: The spindle is supported by bearings that allow it to rotate smoothly and with minimal friction.

Tailstock

The tailstock is a movable component that sits opposite the headstock on the lathe bed. It provides support and stability to the workpiece during turning.

- Tailstock Spindle: The tailstock spindle is a hollow shaft that can be moved in and out of the tailstock. The tailstock spindle is used to support the workpiece by applying pressure against it.

- Tailstock Quill: The tailstock quill is the mechanism that allows the tailstock spindle to move in and out of the tailstock.

- Tailstock Base: The tailstock base provides a solid foundation for the tailstock and allows it to be moved along the lathe bed.

Lathe Bed

The lathe bed is the foundation of the lathe, providing a rigid and stable platform for the headstock, tailstock, and tool rest.

- Bed Material: The bed is typically made of cast iron or steel, materials known for their durability and resistance to vibrations.

- Bed Length: The length of the lathe bed determines the maximum length of workpiece that can be turned.

- Bed Rails: The lathe bed features rails that guide the tailstock and tool rest.

Tool Rest

The tool rest is a critical safety component that provides a platform for the turning tools and helps keep them stable during operation.

- Tool Rest Base: The tool rest base is mounted to the lathe bed and allows the tool rest to be adjusted for height and position.

- Tool Rest Arm: The tool rest arm extends from the base and provides a platform for the turning tools.

- Tool Rest Adjustment: The tool rest can be adjusted in height and position to ensure the turning tools are positioned correctly relative to the workpiece.

Materials for DIY Wood Lathes

Common materials used for constructing DIY wood lathes include:

- Steel: Steel is a strong and durable material suitable for making the lathe bed, headstock, tailstock, and other components.

- Cast Iron: Cast iron is another robust material often used for lathe beds, providing excellent vibration dampening properties.

- Wood: While less common for critical components, wood can be used for constructing the lathe bed and other parts, particularly in smaller, simpler DIY lathes.

- Aluminum: Aluminum is a lightweight and machinable material that can be used for various parts, including the tool rest and other components.

Designing and Planning Your DIY Wood Lathe

Designing and building a DIY wood lathe is a rewarding project that allows you to customize a tool to meet your specific needs and budget. This section will guide you through the process of designing your lathe, considering factors like size, power, and features, and choosing the right materials and tools for construction.

Determining the Lathe’s Size

The size of your lathe will determine the maximum length and diameter of the wood you can turn. Consider the types of projects you plan to undertake and the space you have available for your lathe.

- Small Lathe: Ideal for smaller projects like pens, bowls, and ornaments. These lathes typically have a swing of 12 inches or less and are suitable for beginners.

- Medium Lathe: Offers a wider range of turning possibilities, accommodating larger projects like table legs, spindles, and bowls. These lathes usually have a swing of 12 to 24 inches.

- Large Lathe: Designed for turning large pieces of wood, such as furniture parts, tabletops, and even boat hulls. These lathes typically have a swing of 24 inches or more.

Choosing the Right Power Source

The power source for your lathe will determine the speed and torque available for turning. The power source should be sufficient to handle the size and type of wood you plan to turn.

- Electric Motor: The most common power source for DIY wood lathes. Electric motors offer a wide range of speeds and torque, and are readily available. You can choose from single-phase or three-phase motors, depending on your power requirements.

- Gas Engine: An alternative power source, especially if you lack access to electricity. Gas engines offer high torque but can be noisy and require maintenance.

Essential Features to Consider

While building your lathe, consider including these features for improved functionality and safety.

- Variable Speed Control: Allows you to adjust the speed of the lathe for different turning tasks and wood types.

- Reverse Rotation: Enables you to turn the workpiece in the opposite direction, which can be useful for certain techniques.

- Tool Rest: Provides a stable platform for your turning tools, improving safety and accuracy.

- Tailstock: Supports the end of the workpiece, preventing it from wobbling or moving during turning.

- Safety Features: Include features like emergency stop buttons, safety shields, and clear visibility of the turning area.

Selecting the Right Materials

The materials you choose for your lathe will impact its durability, stability, and overall performance.

- Frame: Consider using sturdy materials like steel, aluminum, or heavy-duty wood for the lathe’s frame. Steel offers excellent strength and durability, while aluminum is lighter and less prone to rust. Heavy-duty wood, such as oak or maple, can also provide a stable base.

- Bearings: Choose high-quality bearings to ensure smooth and reliable rotation. Ball bearings are a common choice for wood lathes, providing low friction and high load capacity.

- Spindle: The spindle is the rotating shaft that holds the workpiece. Select a strong and durable material like steel for the spindle. The spindle should be accurately machined to ensure smooth rotation and minimize vibration.

Choosing the Right Tools

Building a DIY wood lathe requires a range of tools, including:

- Measuring Tools: A tape measure, calipers, and a protractor are essential for accurate measurements and cutting.

- Cutting Tools: A metal saw, a hacksaw, and a drill are necessary for cutting and shaping the lathe’s components.

- Machining Tools: A lathe, a milling machine, or a drill press can be used for machining specific components.

- Welding Equipment: If you plan to use steel or aluminum for the frame, you will need a welding machine and appropriate welding materials.

- Fasteners: Use high-quality bolts, nuts, and washers to secure the lathe’s components.

Step-by-Step Plan for Building a Basic DIY Wood Lathe

Here’s a step-by-step plan for building a basic DIY wood lathe:

- Design and Draw Plans: Start by sketching out your lathe design, considering the features you want to include and the materials you will use.

- Gather Materials and Tools: Acquire all the necessary materials and tools for construction.

- Build the Frame: Construct the lathe’s frame using the materials you have chosen. Ensure the frame is sturdy and stable.

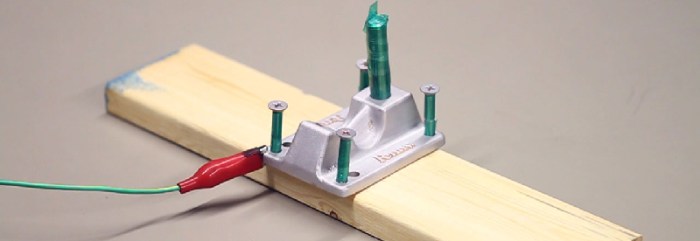

- Install the Bearings: Mount the bearings on the frame, ensuring they are properly aligned and secured.

- Install the Spindle: Attach the spindle to the bearings, ensuring it rotates smoothly and without vibration.

- Install the Tailstock: Mount the tailstock on the frame, ensuring it is adjustable and can be securely locked in place.

- Install the Tool Rest: Attach the tool rest to the frame, ensuring it is adjustable and can be moved easily.

- Install the Power Source: Connect the power source to the spindle, ensuring the motor is properly wired and secured.

- Test and Adjust: Once the lathe is assembled, test it thoroughly to ensure it operates smoothly and safely. Make any necessary adjustments.

Construction Techniques and Tools

Building a DIY wood lathe requires a blend of woodworking and metalworking skills. You’ll be working with wood for the frame and bed, and metal for the headstock, tailstock, and other components. The techniques you use will depend on your experience and the specific design of your lathe.

Woodworking Techniques

Woodworking is the foundation of your lathe’s construction. You’ll be using various techniques to create the frame, bed, and other wooden parts.

- Cutting: Precise cutting is essential for creating the various parts of your lathe. You’ll need a saw, like a table saw or a circular saw, for accurate cuts. A handsaw can also be used for smaller pieces.

- Jointing: Jointing ensures flat, smooth surfaces for your wood pieces, especially when creating the bed and frame. A jointer is ideal for this task, but you can also use a hand plane.

- Planing: Planing is used to smooth and level the surfaces of your wood. A hand plane is a common tool for this, but a power planer can be used for larger projects.

- Drilling: Drilling is essential for creating holes for mounting components and for creating mortise and tenon joints. A drill press or a handheld drill is necessary.

- Sanding: Sanding is used to smooth the surfaces of your wood and create a polished finish. You can use various grades of sandpaper to achieve the desired level of smoothness.

Metalworking Techniques

Metalworking is essential for creating the headstock, tailstock, and other metal components of your lathe.

- Cutting: Cutting metal requires specialized tools like a hacksaw, band saw, or chop saw. These tools are used to shape and size the metal components.

- Drilling: Drilling is essential for creating holes in metal components for mounting and other purposes. A drill press or a handheld drill with appropriate bits is necessary.

- Threading: Threading is used to create screw threads on metal components, allowing them to be connected and adjusted. You can use a tap and die set for this purpose.

- Turning: Turning is used to create round shapes in metal, such as the spindle and other parts of the headstock. A metal lathe is ideal for this, but you can also use a hand-held tool like a file or a rasp.

- Welding: Welding is often used to join metal components together, particularly in the headstock and tailstock. You’ll need a welding machine and appropriate welding rods.

Tools for Building a DIY Wood Lathe

Here’s a table outlining the essential tools you’ll need for building a DIY wood lathe:

| Tool | Description | Use |

|---|---|---|

| Table saw or Circular saw | Used for making precise cuts in wood. | Cutting the bed, frame, and other wooden components. |

| Jointer | Used for creating flat, smooth surfaces on wood. | Creating the bed and frame. |

| Hand plane | Used for smoothing and leveling wood surfaces. | Smoothing and leveling the bed, frame, and other wooden components. |

| Drill press or Handheld drill | Used for drilling holes in wood and metal. | Drilling holes for mounting components, creating mortise and tenon joints, and drilling holes in metal components. |

| Hacksaw, band saw, or chop saw | Used for cutting metal. | Cutting the headstock, tailstock, and other metal components. |

| Tap and die set | Used for creating screw threads on metal components. | Threading the headstock, tailstock, and other metal components. |

| Sandpaper | Used for smoothing and polishing wood surfaces. | Smoothing and polishing the bed, frame, and other wooden components. |

| Screwdrivers | Used for assembling and disassembling components. | Assembling and disassembling the lathe. |

| Wrenches | Used for tightening and loosening nuts and bolts. | Tightening and loosening nuts and bolts on the lathe. |

| Clamps | Used for holding pieces of wood together during assembly. | Holding the bed, frame, and other wooden components together during assembly. |

| Measuring tape | Used for measuring and marking wood and metal components. | Measuring and marking the bed, frame, and other wooden components. |

| Level | Used for ensuring that the lathe is level. | Leveling the bed and frame. |

| Metal lathe (optional) | Used for turning metal components. | Turning the spindle and other parts of the headstock. |

| Welding machine and rods (optional) | Used for joining metal components together. | Joining the headstock and tailstock. |

Safety Precautions for DIY Lathes

Building and using a DIY wood lathe comes with inherent risks. It’s crucial to prioritize safety to prevent injuries and ensure a positive woodworking experience. This section will Artikel essential safety measures for operating a wood lathe, discuss the importance of proper equipment and protective gear, and provide detailed steps for setting up a safe working environment.

Safe Operating Practices

Operating a wood lathe requires careful attention and adherence to specific safety practices.

- Always wear safety glasses or goggles to protect your eyes from flying debris.

- Use hearing protection to safeguard your ears from the noise generated by the lathe.

- Never wear loose clothing or jewelry that could get caught in the rotating parts of the lathe.

- Ensure the work area is well-lit and free of clutter to prevent tripping hazards.

- Keep your hands away from the rotating workpiece and the lathe’s moving parts.

- Use a push stick or a tool rest to guide the workpiece and maintain a safe distance from the rotating parts.

- Never leave the lathe unattended while it’s running.

- Turn off the lathe and disconnect it from the power source before making any adjustments or repairs.

- Use a sharp turning tool and maintain a firm grip on the tool handle.

- Be aware of the direction of rotation of the lathe and the workpiece to avoid accidental contact with the rotating parts.

- Avoid using the lathe when you are tired or under the influence of alcohol or drugs.

Importance of Proper Equipment and Protective Gear, Diy wood lathe

The right equipment and protective gear are essential for safe lathe operation.

- Safety Glasses or Goggles: These protect your eyes from flying debris, dust, and wood chips.

- Hearing Protection: Earplugs or earmuffs are necessary to reduce the noise levels generated by the lathe.

- Work Gloves: Gloves provide a better grip on tools and protect your hands from splinters and cuts.

- Dust Mask or Respirator: These protect your lungs from inhaling wood dust, which can be harmful to your health.

- Push Stick: A push stick helps guide the workpiece away from the rotating parts of the lathe, preventing accidental contact.

- Tool Rest: A tool rest provides a stable platform for your turning tool, reducing the risk of tool slippage and accidental contact with the workpiece.

- Safety Shield: A safety shield can be used to protect the operator from flying debris.

Setting Up a Safe Working Environment

A well-organized and safe work environment is crucial for lathe operation.

- Secure Lathe: Ensure the lathe is securely mounted on a stable base and properly grounded to prevent electrical hazards.

- Adequate Lighting: Proper lighting is essential for visibility and safety. Use a combination of overhead lighting and task lighting to illuminate the work area.

- Clear Work Area: Keep the work area free of clutter, cords, and other potential tripping hazards.

- Fire Extinguisher: Have a fire extinguisher readily available in case of a fire.

- First Aid Kit: Keep a well-stocked first aid kit nearby in case of minor injuries.

Basic Woodturning Techniques

Once you’ve built your wood lathe, it’s time to learn the basics of woodturning. This section will guide you through mounting wood, using various tools, and achieving smooth, accurate cuts and finishes.

Mounting Wood on the Lathe

To begin turning, you need to securely mount your wood on the lathe. This is done using a combination of centers and a drive spur. The centers are metal points that support the wood at either end, while the drive spur engages with the wood to rotate it.

- Choosing the Right Centers: Use a live center for the tailstock end and a dead center for the headstock end. The live center rotates with the wood, while the dead center remains stationary.

- Preparing the Wood: Before mounting, ensure the wood is clean and free of debris. You may need to drill a small hole at the tailstock end to accommodate the center.

- Securing the Wood: Mount the wood between the centers, ensuring it’s aligned and centered. Tighten the tailstock to secure the wood.

- Using a Drive Spur: The drive spur is attached to the headstock and engages with the wood to rotate it. Adjust the drive spur to ensure it’s securely engaged.

Woodturning Tools and Their Uses

There are numerous woodturning tools, each designed for specific tasks. Familiarity with these tools is essential for successful turning.

- Roughing Gouges: Used for removing large amounts of wood quickly. These gouges have a wider, more curved blade than other gouges.

- Spindle Gouges: Used for shaping and creating details on spindle work, like legs and handles.

- Bowl Gouges: Used for creating curved surfaces and shaping bowls. These gouges have a wider blade and a deeper curve than spindle gouges.

- Skew Chisels: Used for making precise cuts and creating sharp edges. They have a beveled blade that is angled to the handle.

- Parting Tools: Used for cutting through wood and separating pieces. They have a narrow, straight blade.

- Scrapers: Used for smoothing and polishing surfaces. They have a flat blade that is held at an angle to the wood.

Tips for Achieving Smooth, Accurate Cuts and Finishes

- Maintain Sharp Tools: Dull tools will result in rough cuts and can be dangerous. Sharpen your tools regularly using a honing guide and a sharpening stone.

- Use the Right Tool for the Job: Select the appropriate tool for the specific task you’re performing. This will ensure the best results and reduce the risk of accidents.

- Work Slowly and Carefully: Woodturning involves working with high-speed rotation. Take your time and make slow, deliberate cuts.

- Use Light Pressure: Applying too much pressure can cause the tool to dig into the wood, resulting in uneven cuts or tool damage.

- Practice Good Posture: Maintain a comfortable and balanced posture while turning. This will reduce fatigue and improve control.

- Use a Sanding Drum: After shaping the wood, use a sanding drum to achieve a smooth finish. Start with a coarse grit and gradually progress to finer grits.

Advanced Woodturning Techniques

Once you’ve mastered the basics of woodturning, you can explore more complex and intricate projects. This section delves into three advanced techniques: hollowing, spindle turning, and bowl turning. Each technique requires specialized tools and skills, allowing you to create unique and impressive pieces.

Hollowing

Hollowing is a technique used to create hollow forms, such as bowls, vases, and other vessels. It involves carefully removing material from the inside of a workpiece to create a desired shape.

- Tools: Hollowing tools are designed to remove material efficiently while maintaining control. Some common tools include:

- Hollowing gouges: These gouges have a curved blade that allows for precise material removal. They come in various sizes and shapes to accommodate different hollowing tasks.

- Round nose tools: These tools are used for shaping the inside of the hollow form and creating smooth transitions.

- Spindle gouges: These gouges are used for removing material from the outside of the hollow form and creating a smooth finish.

- Techniques: Hollowing involves a combination of cutting and scraping techniques to create the desired shape.

- Cutting: This involves using a gouge to remove material in a controlled manner. The gouge is held at a specific angle and depth to create a smooth, even cut.

- Scraping: This involves using a scraper tool to remove small amounts of material from the inside of the hollow form. This technique is useful for creating a smooth finish and removing any irregularities.

- Safety: Hollowing is a potentially dangerous technique, so it’s essential to take proper safety precautions. Always wear safety glasses and a dust mask to protect your eyes and lungs. Additionally, ensure that the lathe is properly secured and that the workpiece is firmly attached before starting the hollowing process.

Spindle Turning

Spindle turning involves creating cylindrical or tapered forms, such as legs, spindles, and other decorative elements. This technique focuses on shaping the workpiece along its axis of rotation.

- Tools: Spindle turning requires specialized tools designed for creating smooth, precise shapes. Common tools include:

- Skew chisel: This chisel is used for creating smooth, flowing curves and shaping the workpiece along its length.

- Spindle gouge: This gouge is used for removing material from the workpiece and creating a smooth finish.

- Parting tool: This tool is used for cutting the workpiece into smaller sections.

- Turning chisels: These chisels come in various sizes and shapes and are used for shaping and smoothing the workpiece.

- Techniques: Spindle turning involves a combination of cutting, scraping, and shaping techniques to create the desired form.

- Cutting: This involves using a gouge or chisel to remove material from the workpiece. The tool is held at a specific angle and depth to create a smooth, even cut.

- Scraping: This involves using a scraper tool to remove small amounts of material from the workpiece. This technique is useful for creating a smooth finish and removing any irregularities.

- Shaping: This involves using a variety of tools to create the desired shape of the workpiece. This may include rounding, tapering, or creating decorative features.

- Safety: Spindle turning can be dangerous if not done correctly. Always wear safety glasses and a dust mask to protect your eyes and lungs. Additionally, ensure that the lathe is properly secured and that the workpiece is firmly attached before starting the spindle turning process.

Bowl Turning

Bowl turning involves creating hollow, rounded forms, such as bowls, platters, and other decorative vessels. This technique focuses on shaping the workpiece both along its axis of rotation and across its diameter.

- Tools: Bowl turning requires a variety of tools designed for shaping and finishing hollow forms. Common tools include:

- Roughing gouges: These gouges are used for removing large amounts of material from the workpiece. They have a wide, curved blade that allows for efficient material removal.

- Spindle gouges: These gouges are used for shaping the outside of the bowl and creating a smooth finish.

- Bowl gouges: These gouges are designed for hollowing out the inside of the bowl. They have a curved blade that allows for precise material removal.

- Scrapers: These tools are used for smoothing the inside and outside of the bowl and removing any irregularities.

- Techniques: Bowl turning involves a combination of cutting, scraping, and shaping techniques to create the desired form.

- Roughing: This involves using a roughing gouge to remove large amounts of material from the workpiece. This step is used to create the basic shape of the bowl.

- Shaping: This involves using a spindle gouge to shape the outside of the bowl and create a smooth finish. It also involves using a bowl gouge to hollow out the inside of the bowl.

- Finishing: This involves using scrapers and other tools to smooth the inside and outside of the bowl and remove any irregularities.

- Safety: Bowl turning can be dangerous if not done correctly. Always wear safety glasses and a dust mask to protect your eyes and lungs. Additionally, ensure that the lathe is properly secured and that the workpiece is firmly attached before starting the bowl turning process.

Projects for DIY Wood Lathes

A DIY wood lathe opens up a world of creative possibilities. You can transform simple pieces of wood into functional and decorative objects. From everyday items to intricate art pieces, the possibilities are endless.

Beginner Woodturning Projects

Beginner projects are designed to help you familiarize yourself with the lathe and basic woodturning techniques. They are typically smaller in size and require less complex shapes.

- Spindle: A spindle is a simple, cylindrical shape that is often used as a starting point for woodturning. It can be used to create a variety of objects, such as pens, dowels, and even small decorative bowls. The process involves turning the wood into a smooth, even cylinder, and then shaping the ends.

- Small Bowl: A small bowl is a great way to practice basic turning techniques, such as hollowing and shaping. You can start with a simple, round bowl and gradually move on to more complex designs as you gain experience. The process involves turning the wood into a rough bowl shape, then hollowing out the inside using various tools.

- Turned Ornament: Ornamental pieces are a fun way to add a touch of personality to your home. You can create ornaments in a variety of shapes and sizes, using different woods and finishes. The process involves turning the wood into a specific shape, then adding decorative details such as grooves, beads, or patterns.

Intermediate Woodturning Projects

As you gain experience, you can move on to more challenging projects that require more complex shapes and techniques. These projects will help you develop your skills and expand your creative potential.

- Larger Bowl: Larger bowls require more experience and skill, as they involve more complex hollowing and shaping techniques. You can experiment with different wood species and finishes to create unique and beautiful bowls.

- Turned Vase: A turned vase is a great way to showcase your woodturning skills. It requires precise shaping and finishing to create a functional and aesthetically pleasing piece. The process involves turning the wood into a vase shape, then adding decorative elements such as a lip or a base.

- Turned Table Leg: Turned table legs add a touch of elegance and sophistication to any piece of furniture. They require careful shaping and finishing to ensure that they are both strong and aesthetically pleasing. The process involves turning the wood into a leg shape, then adding decorative elements such as a foot or a scroll.

Woodturning Project Examples

| Project | Estimated Time | Skill Level |

|---|---|---|

| Spindle | 1-2 hours | Beginner |

| Small Bowl | 2-4 hours | Beginner |

| Turned Ornament | 1-3 hours | Beginner |

| Larger Bowl | 4-8 hours | Intermediate |

| Turned Vase | 6-10 hours | Intermediate |

| Turned Table Leg | 4-8 hours | Intermediate |

Troubleshooting and Maintenance

Like any mechanical device, your DIY wood lathe requires regular maintenance and attention to ensure it operates smoothly and safely. This section covers common problems you might encounter and provides troubleshooting tips and maintenance practices to keep your lathe in optimal condition.

Identifying and Resolving Common Problems

- Vibration and Noise: Excessive vibration and noise can be caused by various factors. A loose bed, worn bearings, unbalanced workpiece, or improper belt tension can contribute to these issues.

- Inaccurate Speed Control: Problems with the motor, speed control mechanism, or belt slippage can lead to inconsistent speed control.

- Spindle Problems: Worn or damaged spindle bearings, a loose spindle, or a damaged chuck can cause problems with the spindle’s rotation.

- Tool Rest Issues: A misaligned tool rest or a loose tool rest assembly can make it difficult to control the tool and can lead to safety hazards.

- Electrical Problems: Faulty wiring, a blown fuse, or a damaged switch can cause electrical issues with your lathe.

Troubleshooting Tips

- Check for Loose Connections: Start by inspecting all connections, including those for the motor, bed, tool rest, and electrical components. Tighten any loose screws or bolts.

- Balance the Workpiece: An unbalanced workpiece can cause excessive vibration. Ensure the workpiece is properly centered and balanced before turning it.

- Lubricate Bearings: Regularly lubricate the bearings in the spindle, headstock, and tailstock to prevent wear and tear. Use a suitable lubricant for the bearing type.

- Adjust Belt Tension: Check the belt tension and adjust it as needed. A loose belt can cause slippage and inconsistent speed, while a tight belt can put excessive stress on the motor and bearings.

- Inspect Electrical Components: Inspect the wiring, fuse, and switch for any signs of damage or wear. If necessary, replace any faulty components.

Maintenance and Lubrication

Regular maintenance and lubrication are crucial for extending the life of your DIY wood lathe. Here are some essential maintenance practices:

- Clean Regularly: Keep the lathe clean by removing sawdust and debris after each use. This prevents dirt from accumulating and causing damage.

- Lubricate Bearings: Lubricate the bearings in the spindle, headstock, and tailstock with a suitable lubricant, such as grease or oil, according to the manufacturer’s recommendations.

- Check Belt Tension: Regularly check the belt tension and adjust it as needed.

- Inspect Components: Periodically inspect all components for wear and tear, including the spindle, bearings, chuck, tool rest, and electrical components. Replace any damaged or worn parts.

By building your own DIY wood lathe, you’ll not only gain a profound understanding of the mechanics behind this fascinating tool but also unlock a world of creative possibilities. From simple spindle turning to intricate bowl shaping, your handcrafted lathe will empower you to bring your woodworking visions to life, allowing you to explore the full potential of this ancient craft.

A DIY wood lathe can be a great tool for crafting intricate wooden pieces, and if you’re looking to take on a larger project, you might consider building your own picnic table. There are plenty of free DIY picnic table plans available online, and with a little bit of woodworking experience, you can create a beautiful and functional piece of furniture for your backyard.

Once you’ve mastered the basics of woodworking with a lathe, building a picnic table is a great next step to expand your skills and create something truly unique.